Floor Armor Garage / Car Part Floor Coating

About Garage Floor Coating

One of the toughest and most durable coating that you can apply on a garage or car park floor in today’s world is an epoxy coating. Not only it protects your garage or car floor, it can instantly transform your boring or ugly cement into a professional looking floor of clean, semi-glossy, showroom-quality floor. Since the garage/car park is fast becoming more than just a place where you park your car, the benefits of garage/car floor epoxy have quickly made it one of the top choices for garage flooring today.

One of the toughest and most durable coating that you can apply on a garage or car park floor in today’s world is an epoxy coating. Not only it protects your garage or car floor, it can instantly transform your boring or ugly cement into a professional looking floor of clean, semi-glossy, showroom-quality floor. Since the garage/car park is fast becoming more than just a place where you park your car, the benefits of garage/car floor epoxy have quickly made it one of the top choices for garage flooring today.

Glo-Protek FLOOR ARMOR Garage / Car Park Floor Coating is a two component, solvent free, non-hazardous, high solid formulated epoxy coating system designed for finishing concrete garage floors that are in good sound condition. Cracks and cavities on floor should be cured with sealant. It is not intended for use on potholes or floors that have moisture problem.

Features of Floor Armor

Solvent Free Epoxy Formulae

Easy to Use and Apply

Long Life Durability

Protection against dirt, dust and bacteria.

High Class Appearance

Easy to Maintain and clean

Moisture and Stain resistant

Can handle hot tyre pick-up

Great for basement, garage and open parking

Insures Hygiene

What's the problem?

Perhaps you have an old dusty garage floor that you would like to make better use of, you also want it to look good, safe and hygienic. Maybe the surface is also quite rough, in need of repair and not safe for children or elders.

Perhaps you have an old dusty garage floor that you would like to make better use of, you also want it to look good, safe and hygienic. Maybe the surface is also quite rough, in need of repair and not safe for children or elders.

What's the solution?

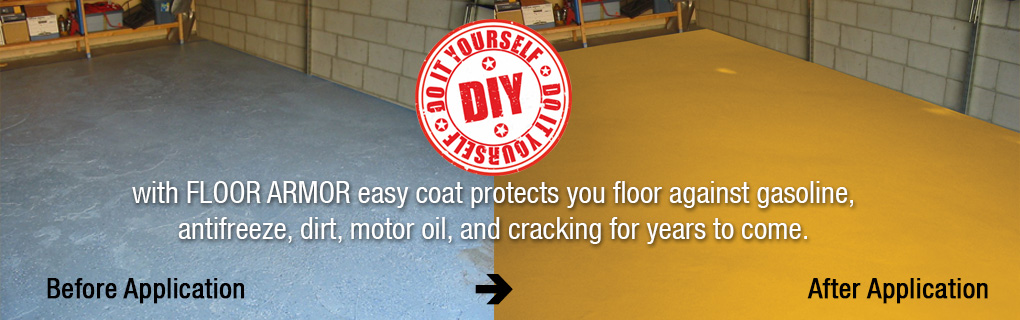

Glo-Protek FLOOR ARMOR KIT is an easy coat that protects against gasoline, antifreeze, dirt, motor oil, and cracking for years to come.

Glo-Protek FLOOR ARMOR KIT is an easy coat that protects against gasoline, antifreeze, dirt, motor oil, and cracking for years to come.

Before Application Note:

- Clear all the loose floor and repair the damage area or potholes by appropriate means.

- Remove all the stains of oil, gasoline with mild soap water.

- After washing wait for atleast 24-48hrs for the surface to get completely dry and moisture free.

- Clean the surface of the floor using a wet cloth to remove all the dirt and dust.

- Apply Glo-Protek Floor Armor after the floor is completely dried.

Product Application:

- To apply the Glo-Protek Floor Armor system, pour all of part B into part A.

- Mix it thoroughly with the stirrer stick provided for at least 3-4minutes.

- Add the provided colour pigment (if colour is not premixed). Stir it thoroughly again for 3-4 minutes.

- Do not leave the mixed product in direct sunlight, stir the mixture one more time before applying.

- Mark the perimeter of the floor along the wall in about 6-inch running using the brush provided before beginning with the roller application. And for car parking demark the area to be coated by masking tape on all the four boundaries.

- Once the entire perimeter is coated, use the roller, pour the mixture into the tray and then apply an even coat of Glo-Protek Floor Armor onto the surface.

- Continue in this manner until the entire floor is complete.

- The surface should be ready for light foot traffic in about 20-24 hours.

- Allow the floor to cure for 3 days before parking vehicles on the surface.

- Apply the product only when air, material, and surface temperatures are between 10-42°C (50-107.6°F). The relative humidity should not be greater than 85%.

Clean-Up

- Glo-Protek Floor Armor is a low odour eco-friendly coating and hence clean-up is easy.

- Just use soap and water to clean your hands and tools.

- Wash tools and equipment with any solvent (kerosene preferable) and a mild detergent immediately after use.

- Clean the surface of the floor using a wet cloth to remove all the dirt and dust.

- Clean up drips or spatters immediately with water as dried paint is very difficult to remove. Properly dispose of all soiled rags.

| Appearance | Semi-gloss |

|---|---|

| Colour | GREY, YELLOW, BLUE and GREEN |

| Density | 1.33 kg/ltr. ±0.03 (mixed product) |

| Solids Content | 100% by volume (mixed product) |

| Viscosity | >140 KU / Krebs Stormer Units at 20°C |

| Recommended film thickness | 150 micron DFT |

| VOC-content max. 0 g/l mixture | 0 g/l Zero VOC |

| Drying times at 30°C/50% r.h. | To touch : 16 hours, Full hardness : 3 days, For immersion : 10 days |

| Coverage Theoretical | 6.1 m²/kg at 150 micron DFT |

Actual curing time depends on the composition of the content (substrate).

Heat resistance: 150°C (dry heat) at elevated temperatures discolouration may occur. 50°C (immersion or wet heat).

Practical: Practical coverage depends on many factors such as porosity and roughness of the substrate and material losses during application.

Apperance

Dries to a semi-gloss finish. Solid base colour with a colour-fleck finish. Available in Grey, Yellow, Blue, Green and Tan colours, based on quantity.